Understanding the Role of a Camshaft Manufacturer in Diesel Engine Parts

The automotive and diesel engine industry is a complex interplay of various components that must work seamlessly together to ensure efficient performance. Among these components, the camshaft plays a pivotal role in enabling the engine to operate smoothly. In this article, we delve into the critical contributions of a camshaft manufacturer, explore the intricacies of diesel engine parts, and highlight the importance of reliable spare parts suppliers, with a focus on the site client-diesel.com.

The Significance of Camshafts in Diesel Engines

At the heart of every diesel engine lies an intricate system of parts that influence its overall functionality. The camshaft is a fundamental component that plays a significant role in regulating the timing and operation of the engine’s valves. Without a properly functioning camshaft, the engine cannot perform efficiently, which could lead to a variety of issues including reduced power, increased emissions, and a shorter lifespan of the engine.

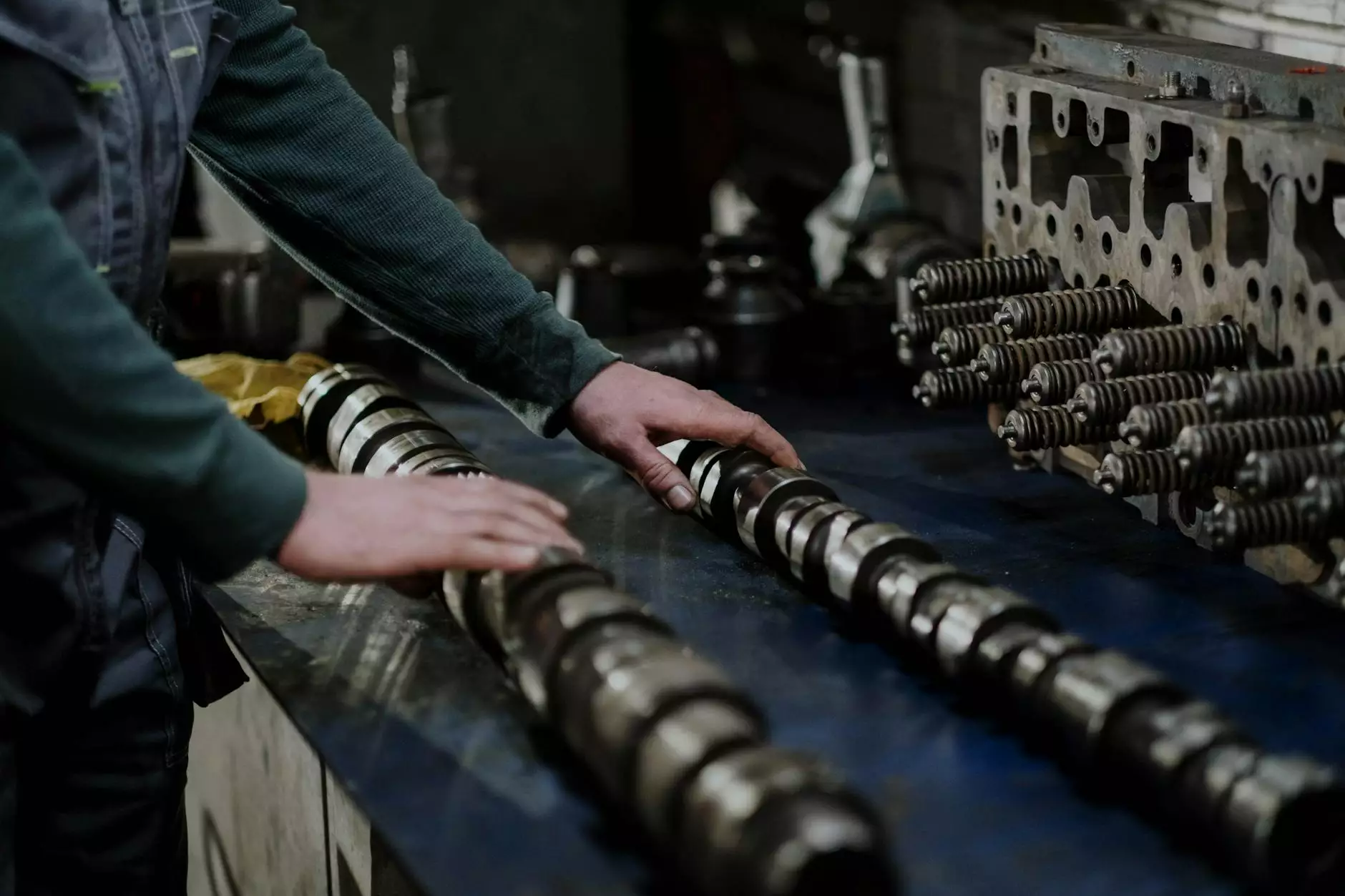

What is a Camshaft?

A camshaft is a rotating shaft that has a series of cam lobes attached to it. These lobes push against the engine's valves, opening and closing them at precise intervals. This action regulates the flow of air and fuel into the cylinders, which is essential for combustion. In diesel engines, the camshaft's timing is particularly critical because the combustion process relies heavily on the precise timing between fuel injection and valve operation.

Types of Camshafts

Camshafts can vary based on their design and intended application. Here are some common types:

- Overhead Camshaft (OHC): Commonly found in modern engines, OHC designs place the camshaft above the cylinder head.

- Pushrod Camshaft: Found in older engines, this setup uses pushrods to actuate the valves.

- Dual Overhead Camshaft (DOHC): This design features two camshafts per cylinder head, enhancing performance and efficiency.

The Role of a Camshaft Manufacturer

Choosing the right camshaft manufacturer is pivotal for the performance of any diesel engine. A quality manufacturer ensures that the camshafts they produce are reliable, durable, and perform optimally under varying engine conditions. Here are a few key responsibilities of a camshaft manufacturer:

Quality Assurance

Quality assurance is critical in the manufacturing process. Manufacturers need to adhere to strict industry standards to produce camshafts that withstand the rigors of diesel engine operation. This includes meticulous inspections and testing of materials and final products.

Innovative Engineering

With advancements in automotive technology, a camshaft manufacturer must embrace innovative engineering practices. This includes using advanced materials and manufacturing techniques such as CNC machining and 3D modeling to create highly precise components.

Customization

Each diesel engine is different, requiring unique specifications for its camshaft. A reputable manufacturer should offer customized options tailored to specific engine requirements, enhancing the engine's overall performance.

Importance of Reliable Spare Parts Suppliers

In addition to a skilled camshaft manufacturer, sourcing components from reliable spare parts suppliers is crucial for the longevity and functionality of diesel engines. Here are several factors to consider:

Quality of Parts

Suppliers that offer high-quality spare parts ensure that all components, from camshafts to fuel injectors, meet OEM standards. Quality parts not only improve engine performance but also enhance durability and reliability.

Comprehensive Inventory

Reliable spare parts suppliers should maintain a comprehensive inventory of various engine components. This broad selection allows customers to find everything they need in one location, saving time and reducing the hassle of coordinating with multiple suppliers.

Competitive Pricing

Competitive pricing is necessary for maintaining a healthy business margin while ensuring that customers receive value for their investment. A reputable supplier will offer fair pricing without compromising on quality.

Understanding the Manufacturing Process of a Camshaft

The process of manufacturing a camshaft is intricate and requires precision engineering. Here’s an overview of the key stages involved:

Material Selection

The choice of material significantly impacts the performance of a camshaft. Manufacturers typically use high-strength steel alloys or cast iron, which can withstand high temperatures and stresses. Such materials ensure longevity and reliability in performance.

Machining

Once the material is selected, the camshaft undergoes machining processes that shape the component accurately. Advanced CNC (Computer Numerical Control) machines are often employed to ensure precision in every detail, from the cam lobes to the shaft itself.

Heat Treatment

Heat treatment is essential to enhance the physical properties of the camshaft material. This process increases hardness and improves resistance to wear, thus extending the component's life.

Finishing

Finishing processes, including grinding and polishing, are conducted to achieve the desired surface finish. This ensures that the camshaft operates smoothly and efficiently within the engine.

Quality Control in Camshaft Manufacturing

Quality control is a critical aspect of the manufacturing process. It ensures that every camshaft produced meets strict performance and durability standards. Here are some key quality control measures that should be in place:

Dimensional Inspection

Every camshaft must undergo strict dimensional inspection to confirm that it meets the specified tolerances. This step is vital to guarantee proper fitment and performance in the engine.

Performance Testing

In addition to physical inspections, manufacturers should conduct performance testing to assess the camshaft's functionality under operational conditions. This may involve using test engines or simulation environments to study how the camshaft performs.

Feedback Mechanisms

Establishing feedback mechanisms from customers and end-users helps manufacturers identify potential issues and areas for improvement in their products. Continuous feedback ensures that manufacturing processes evolve to meet changing industry demands.

Conclusion: The Future of Camshaft Manufacturing in Diesel Engines

The future of the automotive industry is increasingly leaning toward efficiency, sustainability, and innovation. As automotive technology continues to advance, the role of the camshaft manufacturer in producing high-quality diesel engine parts will only expand. Companies like client-diesel.com are key players in this industry, offering reliable solutions for spare parts supply and contributing to enhanced engine performance.

By focusing on quality, innovation, and customer satisfaction, camshaft manufacturers can ensure that diesel engines operate at optimal levels, thereby meeting the ever-increasing demands of the market. Whether consumers are looking for performance upgrades or reliable replacements, the right manufacturers and suppliers will provide the necessary components to keep their engines running strong.

Investing in high-quality camshafts through reputable manufacturers and suppliers means investing in the longevity and efficiency of diesel engines, ultimately leading to better performance and reduced operational costs in the long run.